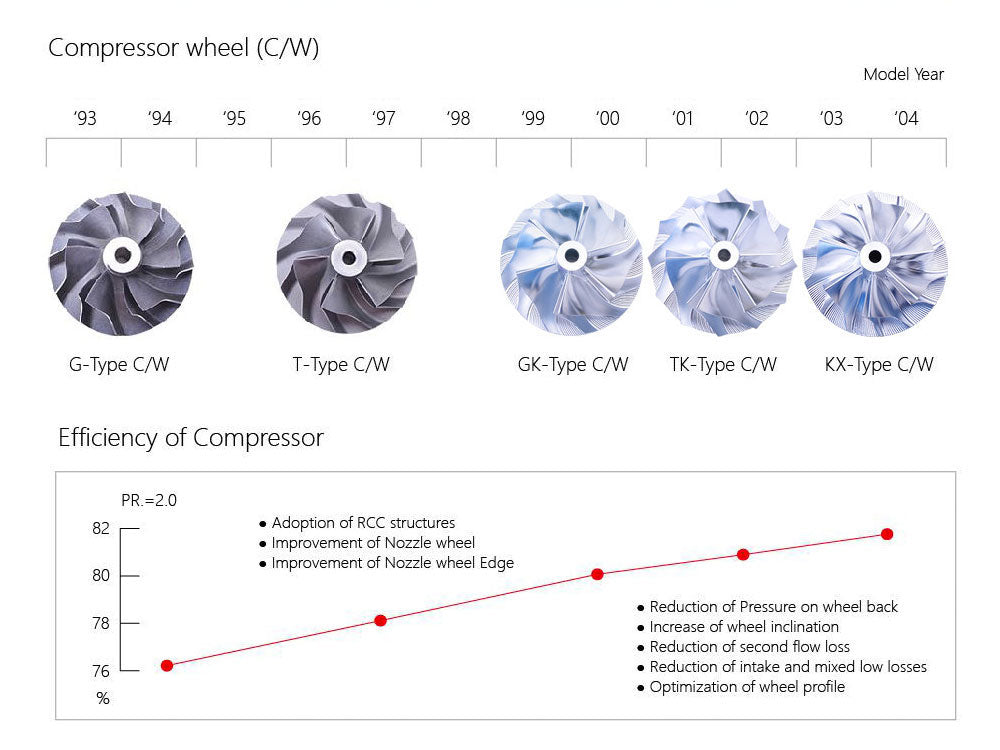

The compressor wheels are typically identified by a number followed by a letter. The number is a specific wheel, and the letter is the shape or blade arrangement (trim). There are G, T, GK, TK, and KX series wheels. "G" series compressor wheels typically feature alternating blade heights and curvature of the fins, whereas "KX" series wheels are all the latest design, featuring 3rd-order surface point milling.

- 3D Design and Three-dimensional Flow Analysis.

- The new type of wheel can reduce the impact loss and eddy loss of airflow. Higher compression ratio and broader flow range available.

- The highest efficiency of the Compressor can reach 81.8%

| Free Surface | Ruled Surface | |

| Process | Point Milling | Flank Milling |

| Machining Time | Slow 120 mins.each | Quick 15 mins.each |

| Characters |

1. Free Surface can be only produced by Point Milling |

1. Ruled Surface can be produced by Flank Milling 2. Low efficiency 3. Only suitable to the very easy design of compressor wheel 4. Mainly for fundamental mechanical engineering such as Centrifugal compressor |